Process Data Management

MPDV Mikrolab GmbH

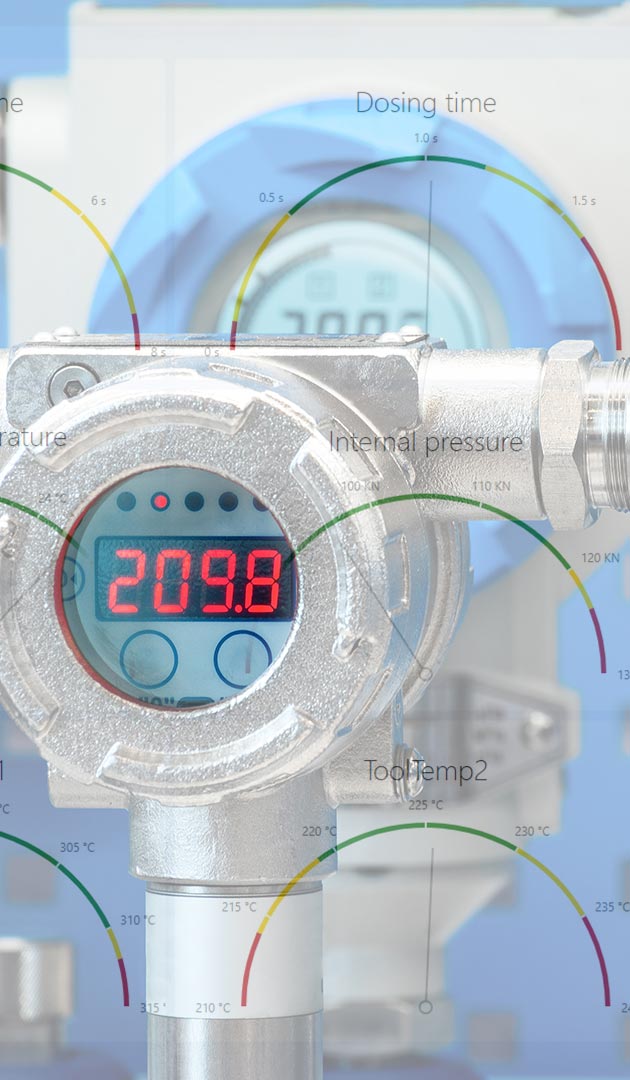

Continuous process data collection

Process data constantly provide information on your production. The mApp displays current information on temperature, pressure, velocity or other measured values. This data must be collected in order to monitor processes on a constant basis.

You can assign process values to specific identifiers, e.g. serial numbers.

Use the mApp Process Data Management to visualize the collected values in real time and to provide other applications with these values via MQTT (publishing).

Optional functions

- Define and process target and limit values

- Calculate new process values from existing values (e.g. conversion factors)

Your benefits

Process data collection helps you increase transparency and keep control of critical production parameters. It also provides the basis for analytics.

Process Data Management promotes sustainability

The monitoring of tolerance and action limits improves the quality of the manufactured products and reduces scrap. At the same time, process data and defined limit values are an early warning system for possible malfunctions.

Technical information

The mApp Process Data Management is part of the HYDRA X category Resource Management.

The automated data collection is performed via Distributed Edge Computing (DEC).

The mApp stores data in the Virtual Production Reality (ViPR) of MPDV's Manufacturing Integration Platform (MIP).

Process data management in the MIP ecosystem

The collected data is used for evaluations, extensive analyses and graphical overviews. MPDV also offers the following mApps:

- Production Process Analysis: extensive evaluation of historic process data

- Shop Floor Monitor: graphical display of current machine and process data

#connectivity #bigdata #realtime #processdata #hydra