Measure Management

MPDV Mikrolab GmbH

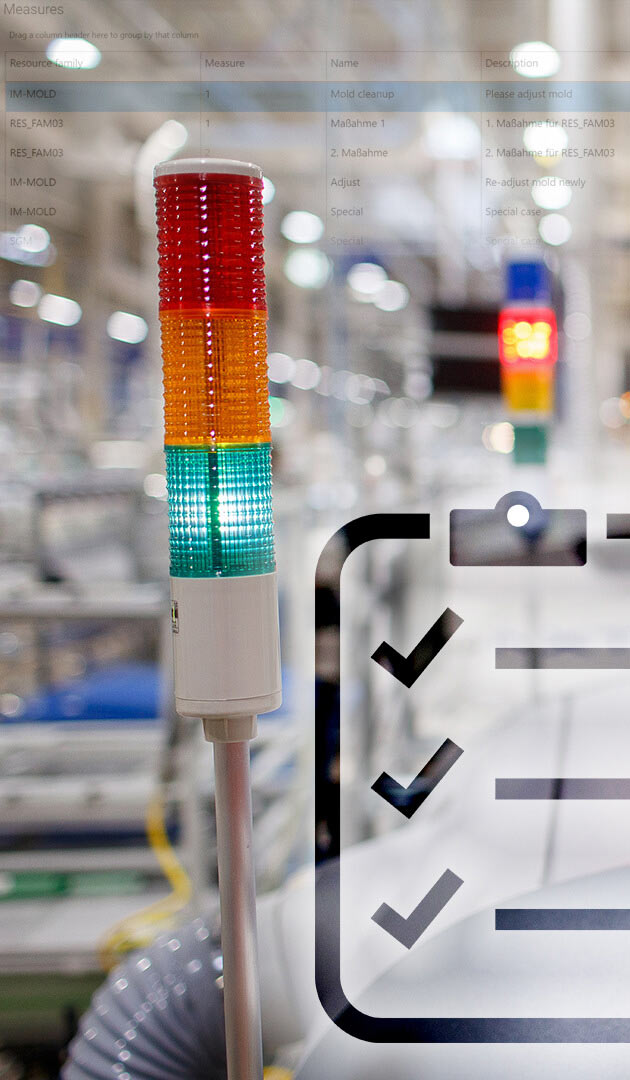

Digital Measure Management

Measures have a significant role in manufacturing. They are used to make improvements and cut down failures. It is mandatory in regulated industries to operate a measure management system that consistently tracks and documents agreed measures.

With the mApp Measure Management, you can define measures in the shop floor, document these and track them throughout. You can monitor due dates for specific tasks by assigning a target date. You can also pass on the measure to a colleague. In addition, you can assign documents (e.g. work instructions, form sheets, drawings or photos of the as-is state) to each measure and references to other objects (e.g. complaint number, inspection task or energy counter).

Your benefits

With digital Measure Management, you secure and monitor the implementation of all kinds of measures. As a result, you meet regulatory requirements and optimize productivity.

Measure Management promotes sustainability

Detected failures and deviations can be tracked systematically and eliminated permanently. To this end, the applications draw on a wide range of shop floor and quality data.

Technical information

The mApp Measure Management is part of the Information Management category of HYDRA X.

The mApp uses and stores data in the Virtual Production Reality (ViPR) of MPDV's Manufacturing Integration Platform (MIP).

Measure Management in the MIP ecosystem

The mApp manages measures from many Smart Factory applications. MPDV also offers the following mApps for this purpose:

- Complaint Management: process complaints efficiently

- In-Production Inspection: collect inspection data in the shop floor.

- Energy Management: make energy consumption transparent

- Maintenance & Service Management: maintain and service resources

- Workflow Management: inform about events

#digitalization #dsfm #collaboration #shopfloormanagement #workflow #hydra