Energy Management

MPDV Mikrolab GmbH

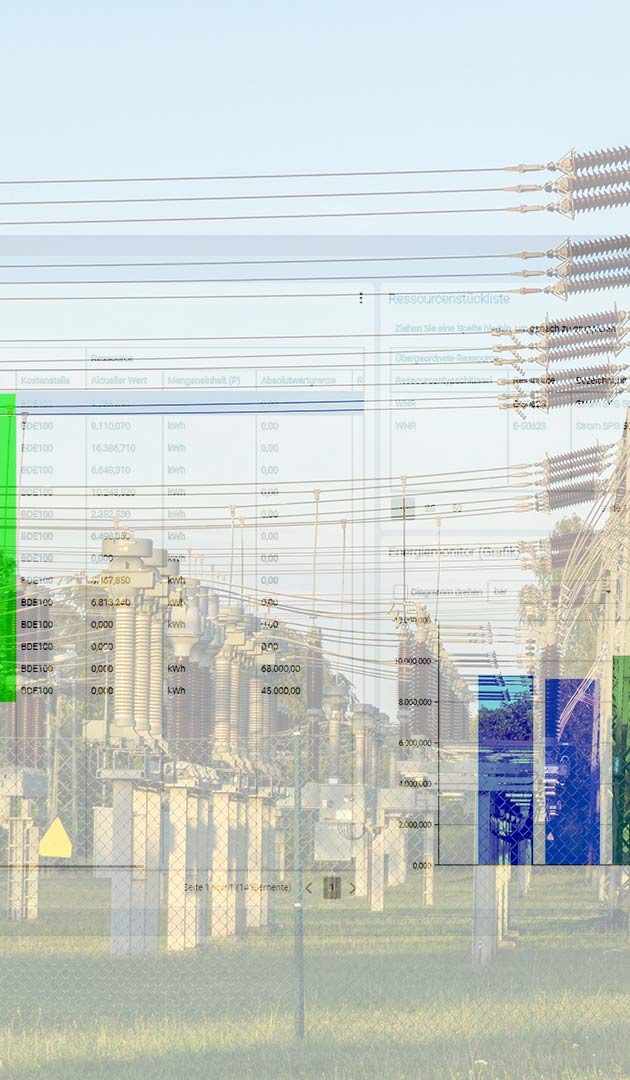

Energy management in manufacturing

Energy costs make up a significant portion of production costs in many industries. A digital energy management is therefore all the more important. You can use the mApp Energy Management to manage counters, to record energy consumption and to assign performance data.

The software uses virtual and calculated counters as well as counter hierarchies to structure the consuming resources and the data. The recorded performance data is visualized in real time and provided to other applications via MQTT (publishing).

If you aim at a certification according to DIN EN ISO 50001, the energy management will support you in collecting data and setting up the required control loops. The performance data can be used to decide on load shedding, for example.

Besides electrical energy, any other type of energy such as gas, compressed air or steam can be recorded and evaluated.

Optional functions

- Plan, perform and monitor manual counter readings

- Analyze energy data and calculate KPIs

- Correlate consumption data with shop floor data or machine statuses

- Sankey diagram showing energy flows within the company

Your Benefits

With Energy Management, you keep track of your consumption and prepare the ground for certification in accordance with DIN EN ISO 50001. At the same time, secure procurement advantages for energy.

Energy Management promotes sustainability

Recording energy consumption creates transparency and supplies information about possible energy losses. Companies use this data to find out where it is worth taking optimization measures.

Technical information

The mApp Energy Management is part of the HYDRA X category Resource Management.

The automated data collection is performed via Distributed Edge Computing (DEC).

The mApp uses and stores data in the Virtual Production Reality (ViPR) of MPDV's Manufacturing Integration Platform (MIP).

Energy Management in the MIP ecosystem

The mApp adds energy consumption to the digital production processes in the Smart Factory. MPDV also offers the following mApps:

- Work Order Execution: collecting order data in the shop floor

- Machine Monitoring: collecting machine data

- Maintenance & Service Management: maintaining resources

- Energy Demand Planning: production planning with APS FEDRA integrating energy consumption

#connectivity #energymanagement #analytics #hydra