SMED / Single Minute Exchange of Die – Smart Factory Glossary

SMED is a method from lean management. The aim of the method is to significantly reduce the setup time of a single machine or an entire production line. Ideally, a machine should be able to switch to a new production process in less than ten minutes – hence the term "single minute" – without disrupting the production flow. Everything from providing new material to setting new operating parameters is part of the setup time.

The method is particularly useful where production processes are frequently changed, for example due to small lot sizes. SMED enables you to respond quickly to market requirements, increases productivity, and contributes to the optimization of the entire value chain.

How to proceed with SMED

Analyzing the current setup processes is the first step to optimizing them with the SMED method. Answering the following questions will help you with your evaluation:

- Which processes are especially inefficient?

- Where is the setup time particularly long?

- Where and why are there fluctuations in the setup time?

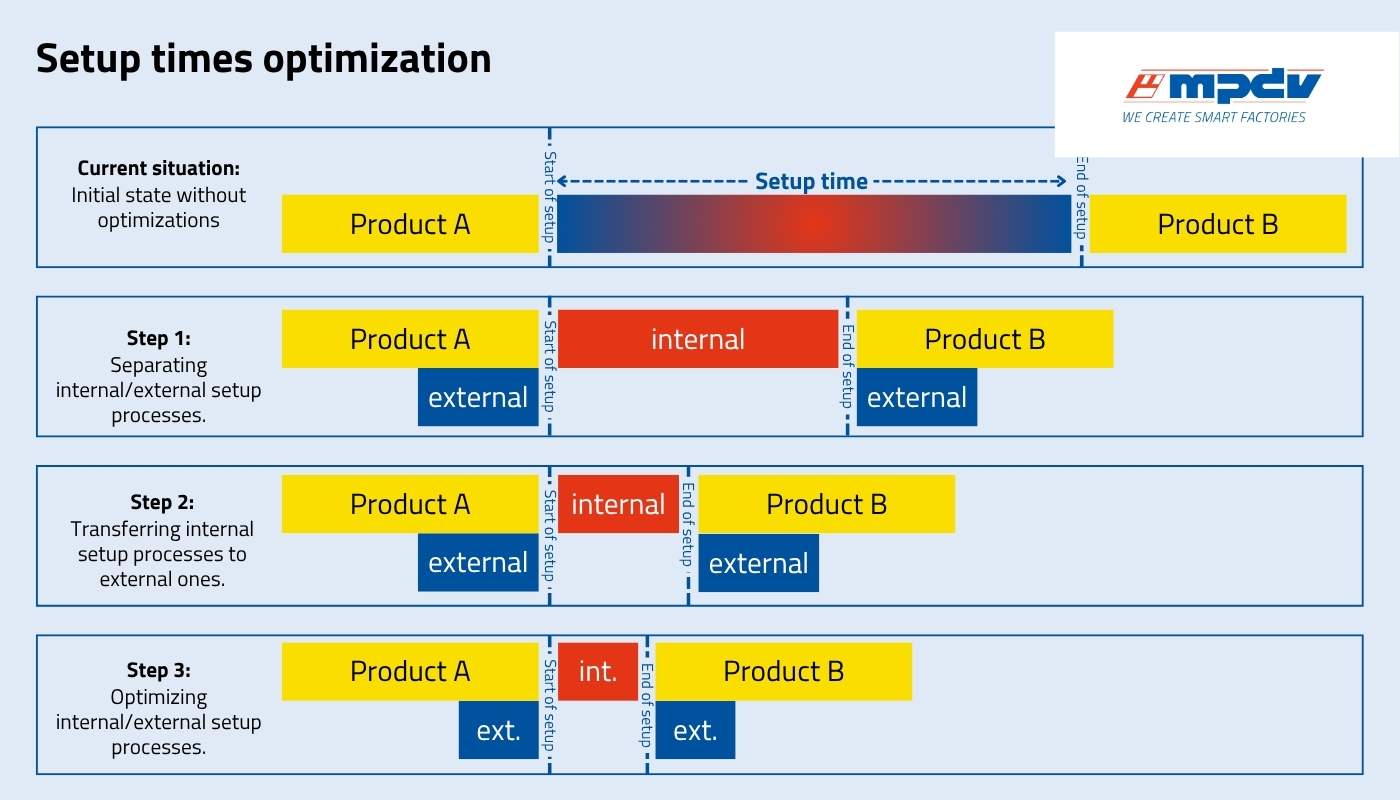

To achieve the objective of fast setup changes, the setup process is divided into separate internal and external steps. Internal steps such as tool changes are only possible when the machine is not running. External steps, such as providing a tool, are also possible while the machine is producing.

Four steps of optimizing setup times

After a detailed analysis of the current situation, the setup processes are optimized using the SMED method according to these four steps:

- Separate internal and external setup processes.

- Transfer internal into external setup processes.

- Optimize and standardize internal and external setup processes.

- Eliminate readjustments by setting parameters precisely during the adjustment process.

Optimization techniques include organizational and technical measures.

Examples for organizational measures

- Prepare changes in production: Setup processes are planned so that you can complete as many steps as possible while the machine is running.

- Standardize workflows: Clear work instructions and checklists for setup processes ensure that every step is performed efficiently and consistently.

- Organize workplaces more effectively: The 5S method ensures that workplaces are clean, organized, and efficient, which can significantly reduce setup times.

Examples of technical measures

- Quick-release devices: Devices that enable tools or parts to be changed quickly and easily minimize downtime. (e.g., clamps instead of screws).

- Modular tool systems: Modular systems allow entire tool groups to be quickly changed instead of individual parts.

- Sensors: Sensors enable early detection of problems and allow setup processes to be adjusted accordingly, minimizing rework.

Benefits of SMED

Reducing setup times is one of the first and most important steps toward making production more responsive. Halving setup times significantly improves flexibility and ultimately productivity. The technical literature reports that many companies have achieved a reduction in setup times of more than 50 percent using the SMED method.

This results in the following advantages:

- Smaller lot sizes: Quick changeovers enable seamless product changes. Manufacturers can therefore switch between different orders more frequently, which also creates greater scope for offering a wider product range.

- Lower inventory: Smaller lot sizes reduce storage costs, reduce waste, and require less space for stored materials. A reduced replenishment time also lowers finished goods inventory.

- Shorter lead times: Standardized setups and reduced downtime increase productivity. Many setup steps can be conducted during ongoing production, minimizing machine downtime.

- Greater flexibility: Smaller lot sizes and optimized workflows enable faster response times to customer requirements and improve on-time delivery.

- Less start-up losses: Start-up losses are minimized thanks to faster restart of production with flawless parts. Start-up losses are rarely included in KPIs as they are often taken for granted

The Executive Manufacturing Center (EMC) can effectively support companies in implementing lean management and SMED. MPDV's in-house consulting brings expertise and proven methods to analyze processes, identify weaknesses, and highlight potential for improvement. Targeted support can increase efficiency, reduce setup times, and optimize production processes, leading to higher flexibility and reducing costs.

Frequently asked questions about SMED

SMED is the abbreviation for Single Minute Exchange of Die, which means tool change in the single-digit minute range. A machine can be set up in less than ten minutes so that production can move seamlessly from the last flawless part of series A to the first flawless part of series B.

An SMED workshop is a hands-on training course that aims to reduce machine and equipment setup times using the SMED method. SMED workshops are often held in the areas of production, maintenance, or logistics. The workshops contribute to increasing flexibility, efficiency, and competitiveness of a company.

An SMED workshop typically proceeds in several phases:

- Analyze current setup processes: The existing changeover procedure is documented through observation, video recordings, or time studies.

- Separate internal and external setup processes: Activities that take place during machine downtime are identified. If possible, they are transferred to external processes that can be completed in parallel during running production.

- Optimize internal setup processes: By using standardized tools or quick-change systems and improving processes, downtimes can be further reduced.

- Standardize: The new processes are documented in work instructions and checklists, staff are trained accordingly, and regular reviews are conducted. This guarantees improvements in the long term.

SMED is a method used in lean management to increase machine and equipment productivity. Flexibility is increased and smaller lot sizes can be achieved. Like other lean management methods, SMED aims to reduce waste. Before the setup time is optimized using the SMED method, a clean and well-organized working environment is created in production with the 5S method.

The SMED system is part of the lean management concept and describes a method for drastically reducing setup times in production. The aim of the SMED system is to optimize setup processes so that they can be performed as quickly and efficiently as possible. Downtimes are minimized and flexibility is increased in production. This is achieved by converting internal setup processes (while the machine is idle) into external setup processes (in parallel with production).

Machine setup time can be reduced by means of various organizational and technical measures.

- In terms of organization, the SMED method helps by converting internal setup processes into external ones, meaning that activities such as preparing tools and materials are already performed while the machine is running. In addition, standardized workflows, checklists, and optimized workplace organization improve efficiency.

- Technically, setup times can be reduced through quick-clamping devices, modular tool systems, and the use of automation technologies. The use of sensors that help detect problems early on can further reduce setup times.

You can tell if SMED is working by looking at different KPIs. First and foremost, the setup time itself and Overall Equipment Effectiveness (OEE) are significant indicators. Regular analyses help to evaluate the progress of SMED implementation and identify further potential for optimization.

- Setup time: The most important KPI is the time used for setup processes. The success is reflected in a significant reduction in setup time, ideally to less than ten minutes.

- OEE: Improved setup times have a positive effect on equipment effectiveness, as downtimes are reduced, and production capacities are better utilized.

- Defect rate: Flawless parts are produced immediately after tool change, minimizing rework and scrap.

Source

- Single Minute Exchange of Die: Wikipedia, 15 March 2025 [online] https://en.wikipedia.org/wiki/Single-minute_exchange_of_die (accessed on 14.05.2025).

Would you like more information? We are happy to help.

Just fill in the form below. We will take care of your inquiry promptly.